Confessions of An Architect Turned Pella Sales Rep

by: Jeff Stetter, AIA, Pella Commercial Sales Rep

This is a sponsored article by Pella

Approximately 3 years this past June, I made the career shift to becoming the Commercial “Sales Rep” for Pella Windows and Doors. Prior to that I was with gbA for over 24 years as a Project Architect. Up until about 3 ½ years ago, I would have told you the last thing I could ever imagine being is a “Sales Rep.” I loved design, the people I worked with, the short commute, and the office environment. “Why did you need the career change?” people ask. To this day, I don’t have a great answer for that. Given the message on the cake gbA got for me, neither did anyone else.

Needless to say, I’ve enjoyed the switch. I was always the “window guy” in the office so becoming a full time window guy has at least some logic… right? Given my Architecture background, I still don’t consider myself a salesman. I like the term “Information Provider” or maybe “Window Concierge”…or “Fenestration Consultant”. The Owner of our Distributorship, Al Herringshaw, may cringe when he reads this, but I seriously try to simply find the best solution for the job. Sometimes that ends up not being Pella. In the end hopefully that approach is appreciated and we’ll have another shot down the road.

OBSERVATIONS OF AN ARCHITECT ON THE OTHER SIDE OF THE SPECIFICATION.

One of the best parts of the job is seeing the drawings and designs that Architects generate. Imagine if we pooled all of our knowledge and resources for all the troublesome details that we struggle with. There’s a solution out there. I’ll often see a detail that is trying to accomplish a certain goal, and yet I’ve seen it done easier and better elsewhere. But often the Architect has run this detail thru the entire project and simply doesn’t have the time or money to redo the detail. So…

Observation #1: Ask for what you are trying to achieve and have details and layouts confirmed by suppliers early and often.

Observation #2: Be kind. I can tell you right now, I provide a ton more work for people who appreciate what I do. I’m kind of hardwired that way. I think most of us are. After submitting a price to contractors, the one that takes the extra 30 seconds to write back and say “Thanks Jeff” I will bend over backwards for. The same with Architects.

Observation #3: Architects should take more advantage of available services. Request Samples, request Preliminary Installation Details, request Budgets, request VE Items up front. Demand more from your reps. Once a wall section is established, send it off and see what kind of installation details are available for that particular wall section. I know there are reps that will give you the same old answer. During my 25 years in Architecture, I don’t believe I ever reused a window detail. Pella has an entire team of Architects, Engineers, and Drafters in Pella, Iowa dedicated to designing window details.

Observation #4: Architects are great people. I’m sure all offices have a few biases towards the design ideas of other offices. It’s important to separate the ideas from the people. I seriously haven’t met an Architect I haven’t liked.

SOME THINGS I’VE LEARNED FROM PELLA:

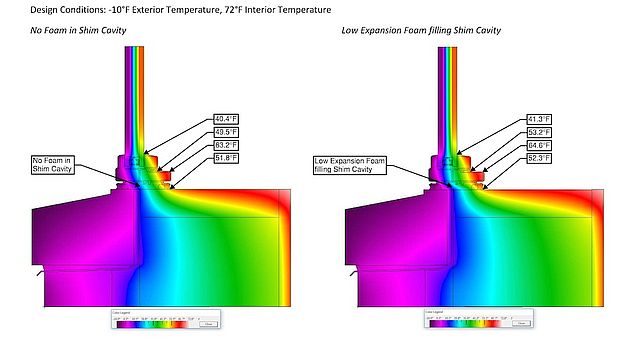

Rainscreen Window Installation

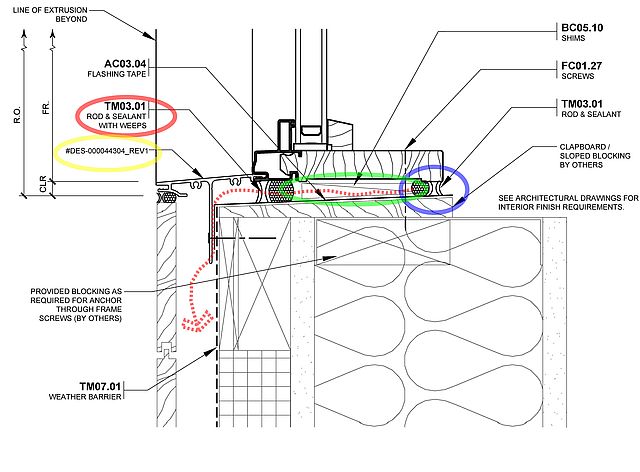

Rainscreen cladding design is almost routine now. Somehow it was lost on me that the rough opening of a window should be designed utilizing rainscreen principles as well. It’s often the desire to fill the RO cavity full to the hilt with spray foam. I did that all the time! Better thermal performance, right? Well it might be slightly better thermal performance (see Figure 2) but you’re basically building a barrier wall system similar to all the Dryvit failures back in the 90’s. Water will get in and then there is no place for it to go, so it will just sit there and rot… Pella requires an open cavity and a path for moisture to travel out of the cavity. Rainscreen principles are also then applied to the design of the window itself which typically has weeping capability for any moisture that may make it within the window unit. See Figure 1.

Sealant and Backer Rod

It’s not uncommon for spray foam to separate from other materials after years of movement. Or the foam was sprayed in a dusty cavity and there was never any seal. When the foam separates, it allows a path for moisture and air to enter the interior of the building. A more robust solution is backer rod and sealant which can move with the expansion and contraction of the adjacent materials.

I also highly recommend that this be accomplished by specialized contractors on larger jobs… Folks that do miles of sealant a year are simply better at it than anyone else.

And don’t allow a sealant joint without a backer rod. Sealants were designed to properly function when installed in a concave hourglass shape. Virtually impossible without backer rod. See Figure 2.

Interior Air Seal

As we’re finding out, the interior air seal is critical. Things such as shims and installation clips make it extremely difficult to get a good continuous seal. So when possible, I highly recommend thru frame fastening or nail flange to avoid the installation clips. Ideally shims should be recessed at least a ¼” from the interior face of the window to allow the airseal to be continuous. In the adjacent photo it’s fairly obvious that trying to seal around the shims is going to be difficult, if not impossible.

Air Sealing tapes are also available from folks like 475 and Siga. I foresee this being an approved method of install in the future, but currently, Pella still requires sealant and backer rod.

Shimming

It’s also important to shim the window at the sill. We know the shimming is there to ensure the window is level, but it is also important to allow a space for incidental moisture to escape. All windows will leak over time and we don’t want the window sitting in a puddle of water. See Figure 3.

Good Fenestration Detailing (See Figure 4.):

1. Integration with the Wall Design

2. Utilization of 4 Envelope Design Principles

a. Deflect (yellow)- head flashings/ ext. seals

b. Drain (green)- open spaces

c. Dry (red)- exit paths/ weeps

d. Divide (blue)- interior air seals/ back damns

Conclusion:

Architects have so much to focus on. In my relatively new role, I’ve enjoyed the opportunity to focus on one aspect of the building process and I look forward to the possibility of helping out on your next project.

Pella is organized into 3 Departments: Commercial/ Trade/ and Retail. We work together as a team with multiple reps in each segment. With 9 lines of windows in 4 materials, we typically have a solution for most applications. Towards the end of the year, I’ll be transitioning into the Architectural Rep position as my esteemed colleague, Dennis O’Rourke will be retiring. I look forward to meeting more of you as the opportunity arises. I welcome any questions or feedback and can be reached at jstetter@ pellasales.com or 802-498-4682. Thanks!

Opinions expressed in AIAVT News are those of the writers to whom they are attributed and not AIAVT, unless specifically stated. Neither this Chapter, nor the Executive Committee, any Chapter committee, nor any of its officers, directors, committee members or employees, in an official capacity as such, shall approve, sponsor or endorse, either directly or indirectly, any public or private enterprise operated for profit, or any material of construction or any method or manner of handling, using, distributing or dealing in any material or product.